The product that I would like to show consists of a new way of paints commercialisation and use for various types of application: from solvent enamels to water-based paints, from anti-rust to wood impregnating agents.

This product is suitable for all types of uses, whether the end user enjoy d.i.y. or working in a professional painting capacity.

The system intends to combine the practical use of spray paints but with the quality and low cost of painting with a professional airbrush.

Plug and Paint

The state of the art

D.i.y. jobs and all those similar painting jobs are normally done using the classic roller or a brush tool and for some very small jobs spray cans can be used. Spray painting provides excellent for coverage on very small areas but is not ideal for coving larger areas given the higher costs and the lower quality.

The use of compressed air spray guns, on the other hand, is restricted to a limited audience of experienced users. In-fact the use of paints and thinners requires some basic knowledge of paint chemistry, which not everyone possess.

Moreover, the use of the spray gun is not always convenient, especially for small jobs: in fact, the use of spray guns involves a long preparation procedure, ability to use the correct dosage of the necessary quantity of paint, knowledge in the selection of specific thinner and mixing of these in the right percentages.

Finally, once the work is completed, it is necessary to carry out a thorough cleaning of the spray gun and in particular the paint container, which is very time consuming and not very eco-friendly given the waste of paint and consumption of diluent for cleaning.

Plug and Paint

The idea

The objective of this system is to provide a product immediately ready for use, that is a varnish already mixed with its specific thinner in the right proportions, in ready cartridges easy to use. This makes such a product suitable for a wide range of uses and users

One of the most important peculiarities of the cartridge system will be the fact that once the work is complete, the non-depleted cartridges can be stored for long periods, as happens with spray cans or with normal paint cans. Once detached from the coupling ring, the valves will guarantee the perfect closure of the cartridge and the preservation of the product for subsequent uses.

The easy of insertion and use of the cartridges will therefore make it possible to use the airbrush also for small jobs and above all, by inexperienced users.

Plug and Paint

The prototype

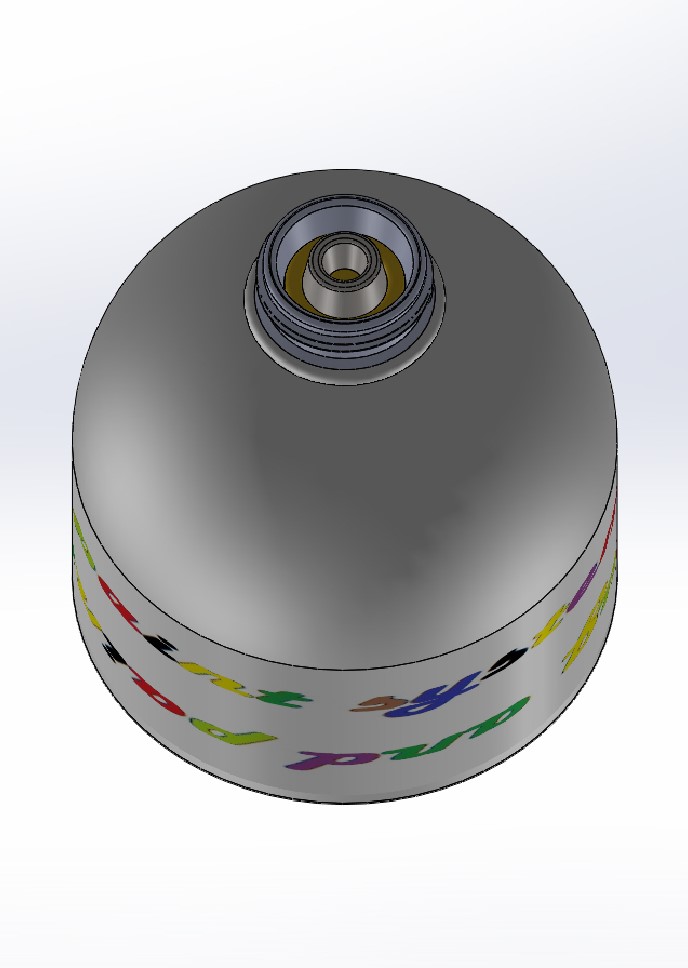

This new system essentially consists of a not-pressurized cartridge made of tinplate, aluminum, plastic, or even tetra-pack.

This cartridge can be used with the common airbrushes already on the market, equipped with a special coupling ring.

The use of this technique will provide the ease of use of a spray can and the quality of a professional airbrush applicable to both small objects and larger surfaces.

Plug and Paint

How it work

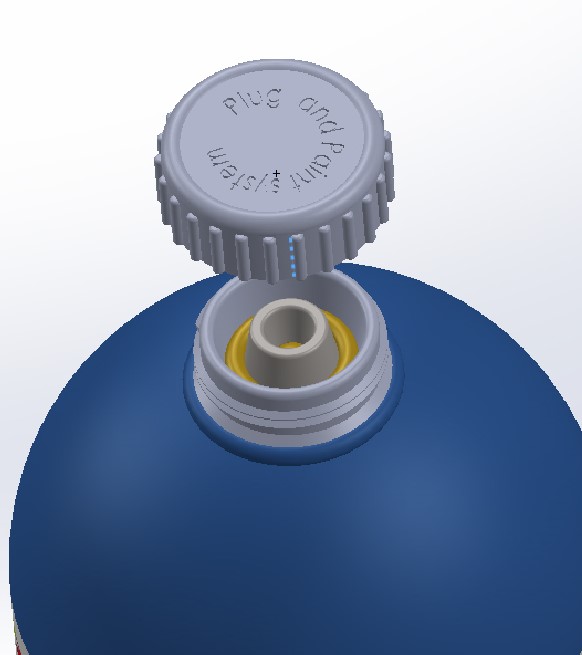

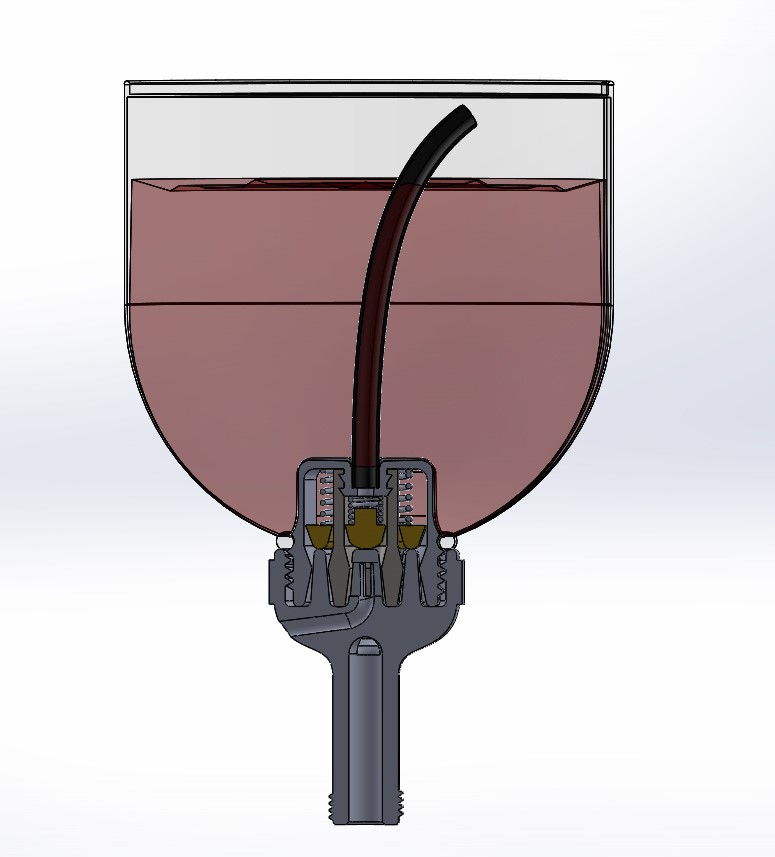

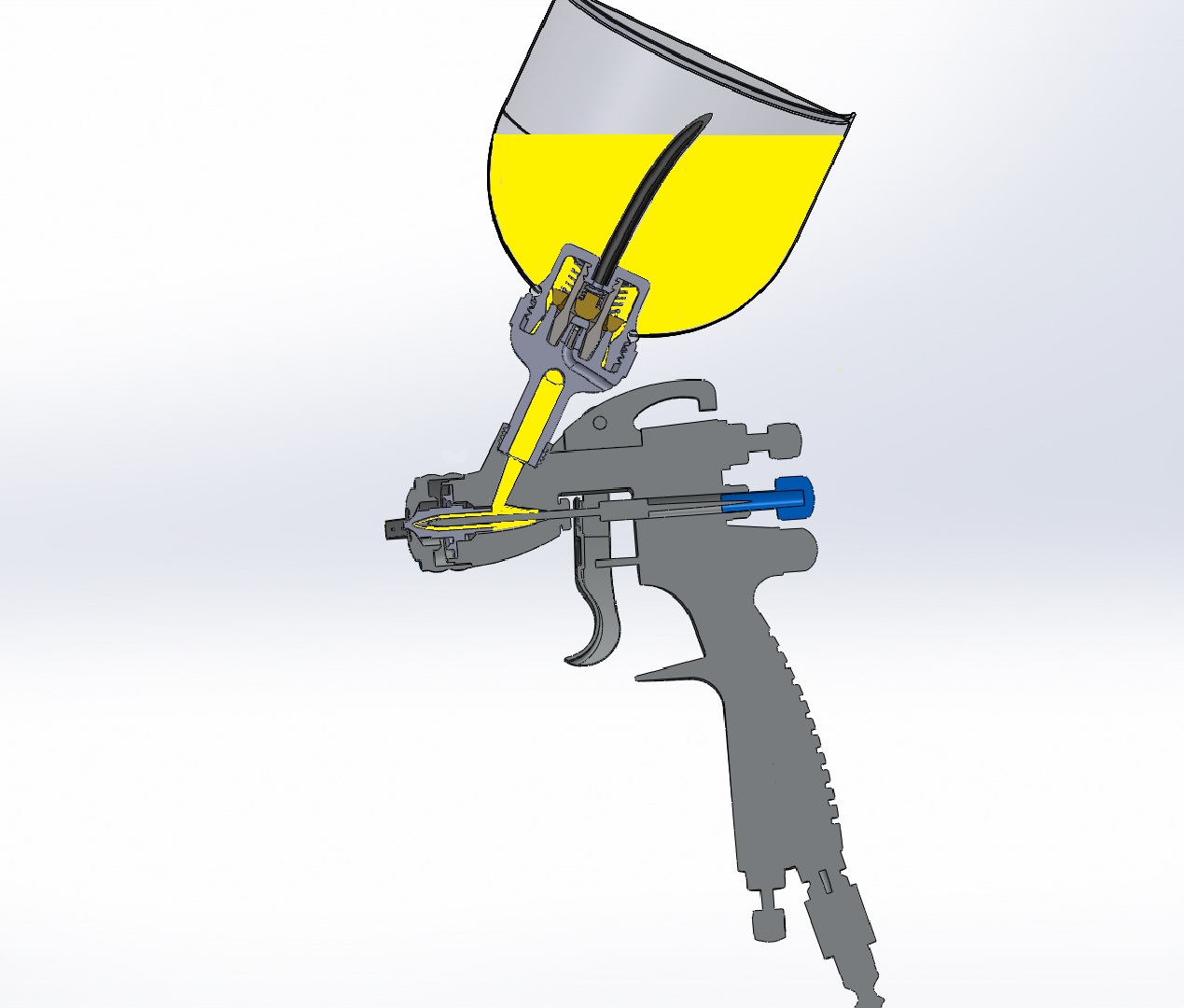

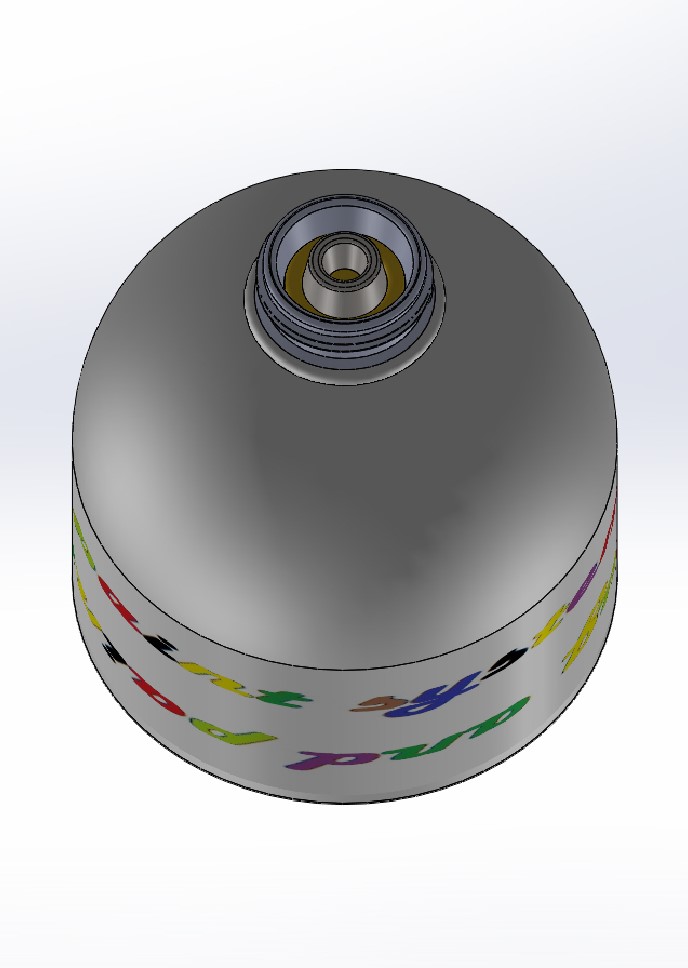

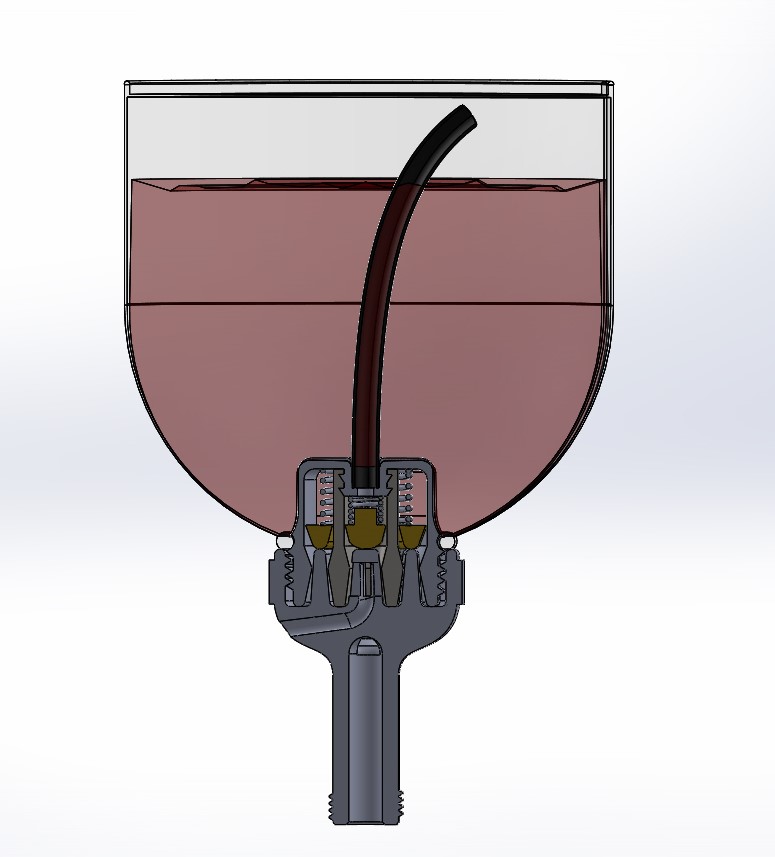

The cartridge is a cylindrical container with a rounded end with a capacity of about 400/500 ml; at the top of the rounded part there is a male threaded coupling that will be screwed onto the special female threaded connection ring, inserted on the airbrush.

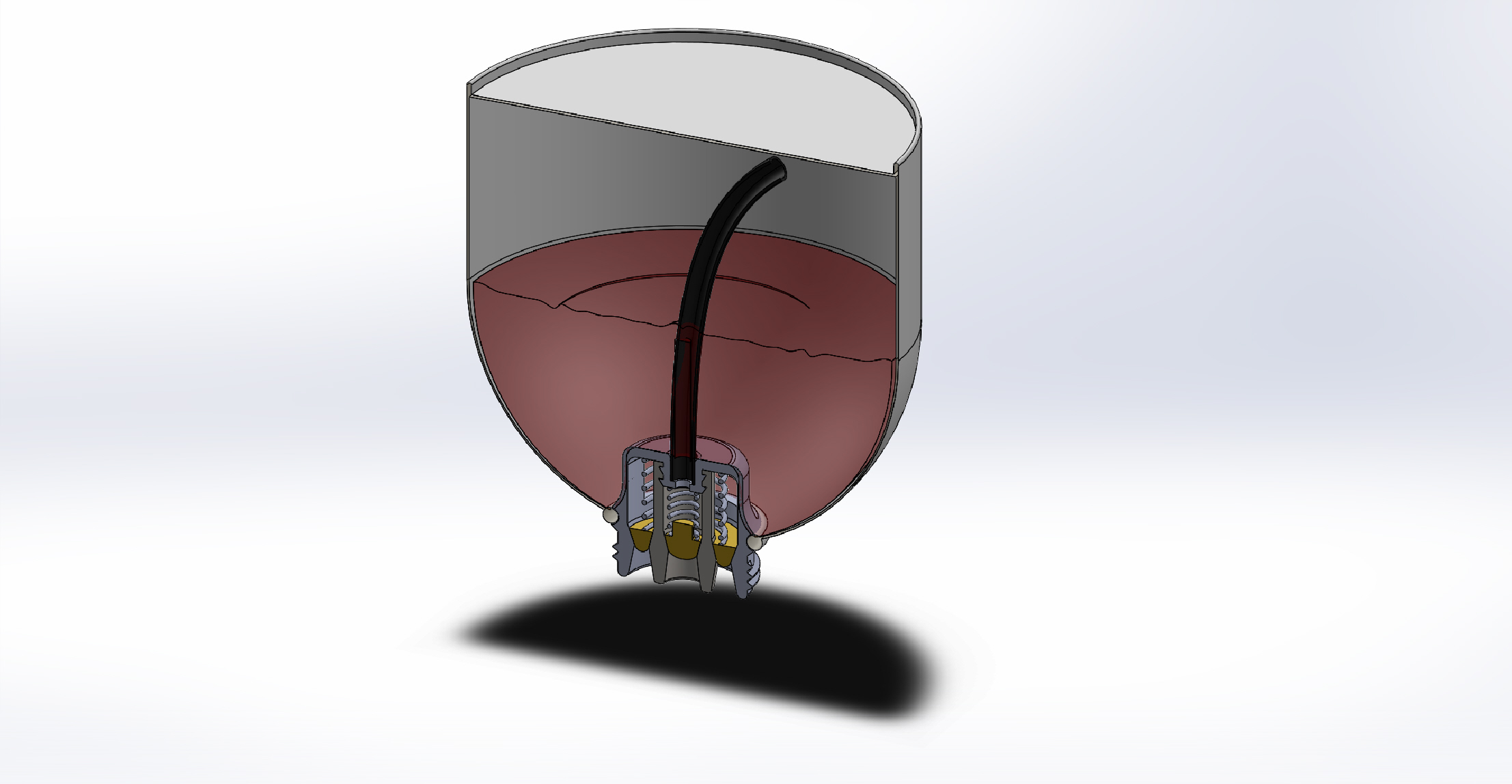

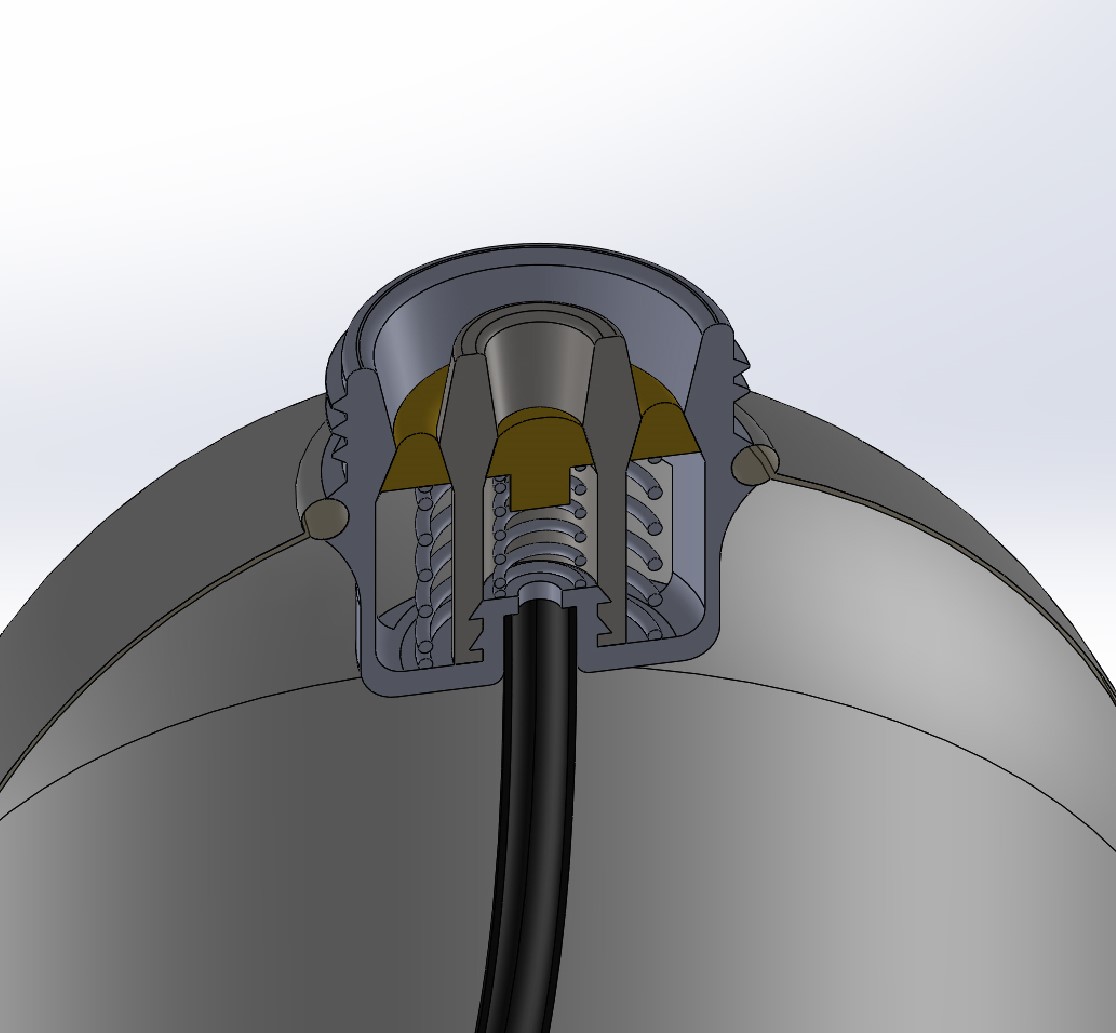

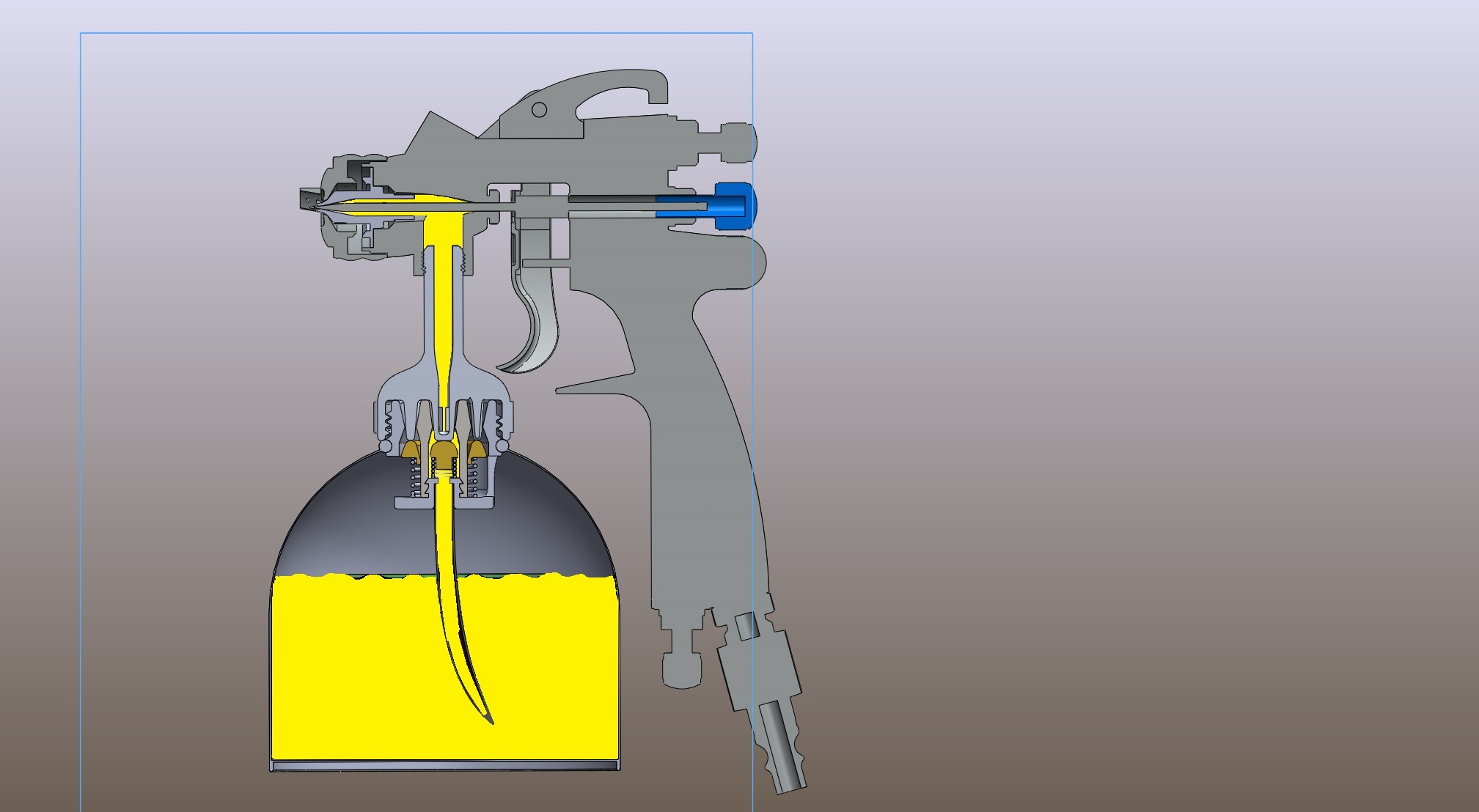

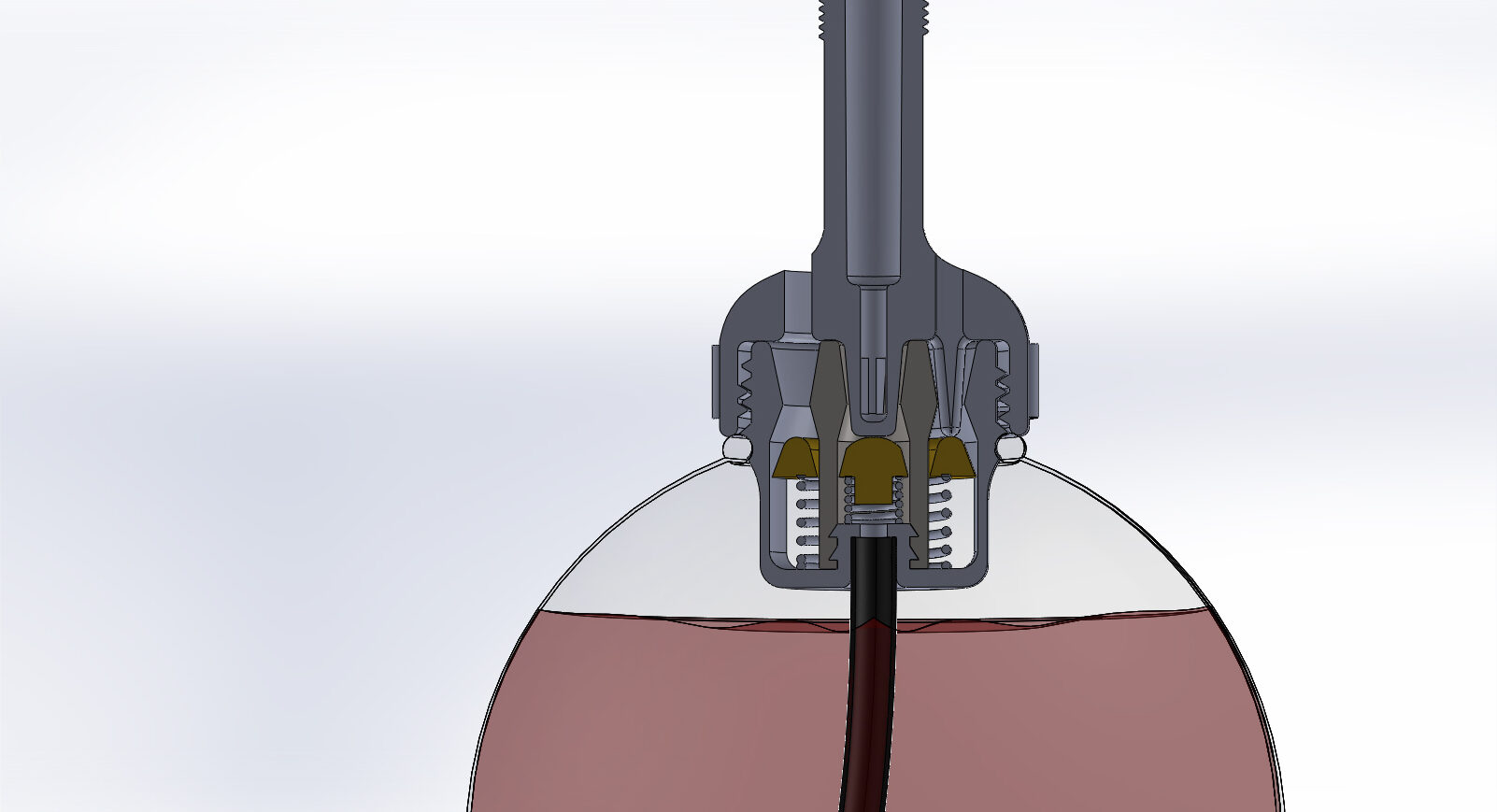

A double concentric valve system is made on the plastic coupling of the cartridge which allows the use of the cartridge without distinction both on lower tank spray guns and in upper tank spray guns.

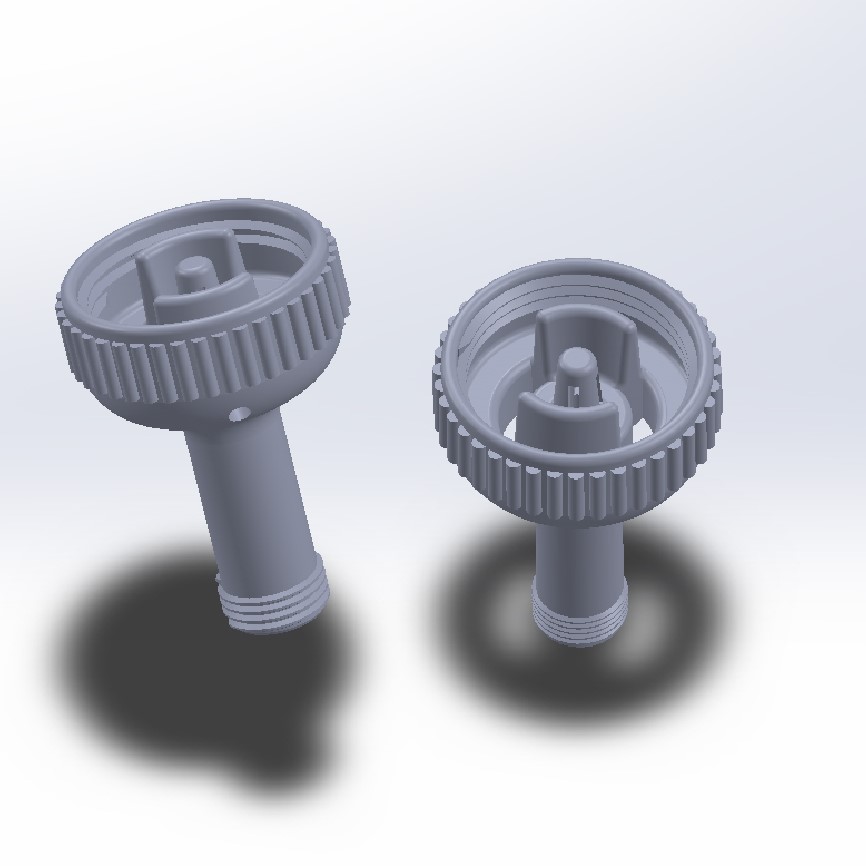

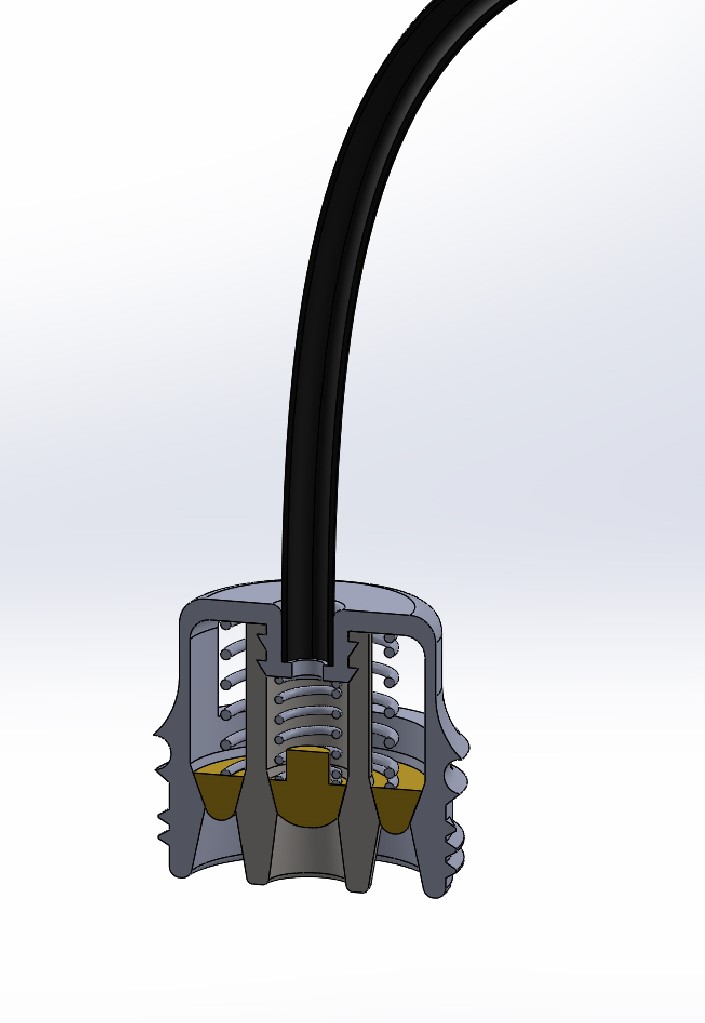

The inner part of the double concentric valve is made up of a special occluder with a rounded tip or a sphere, held closed by a compression spring, and of a ring occluder with a suitable shape for the outer one, also it is held closed by a special spring. The task of these valves is to prevent the paint from leaking and to keep the product inside, not in contact with the external environment, when not inert on the spray guns.

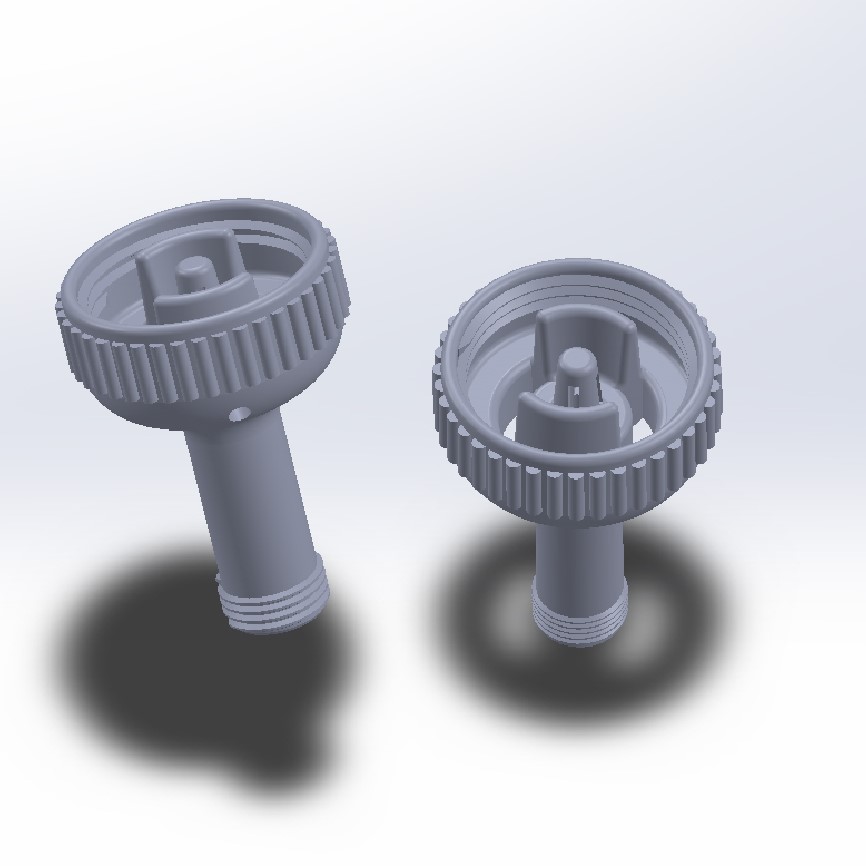

Of these two valves, the ring one will have direct access to the inside of the cartridge, while the inner one will be equipped with a small tube, also made of plastic material, which will reach the bottom of the cartridge opposite the threaded ring nut. The opening of the valves will be activated by the respective pushing spouts present on the special connection rings. There are 2 types of attachment rings, one for airbrushes with a cup on the top and one for airbrushes with a cup on the bottom, and can be made of aluminum, brass or plastic.

In spray guns with cartridge coupling in the upper part, the specific coupling ring nut will allow the cartridge to be inserted, so that the paint comes out by gravity through the ring valve, while from the innermost valve, the one fitted with the tube, the necessary air will enter to compensate for the depression due to the leakage of the liquid.

In spray guns with cartridge connection in the lower part, on the other hand, the specific connection ring nut will allow the withdrawal of the liquid through the innermost valve, equipped with a small tube, then sucked in by the Venturi effect (as occurs in hanging cup spray guns), while, in this case, the ring valve will allow the access of the compensation air.

Inside the cartridges, as in common spray cans, a metal or glass sphere will allow the paint to be mixed by a simple shake.

Once the job is complete, the airbrush can be cleaned easily as it is only required for the nozzle of the airbrush and can be done by just inserting a cartridge of solvent similar to the previous cartridge and spraying for a few seconds until the solvent dispensed looks clean.

The cartridges could also be sold empty, with the upper part open, while the pressure-type closure caps similar to those of normal paint cans, would be equipped with the valve group and sold empty, so that they can be used by colorists equipped of tintometers for the sale of paints on request.

Contact us

+39 3476739080 (ITA)

+44 7783 524138 (UK)

info@plugandpaintsystem.it

Patent

This system is protected by:

Italian patent No. 102018000003785

International patent P.C.T. No. w / 2019/180559

https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2019180559&_cid=P12-K2VRPU-57158-1